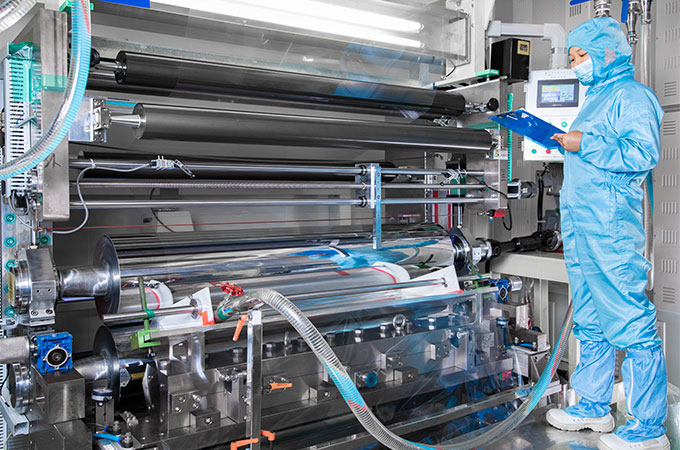

Global Standard Clean Room

Crown utilizes a contaminant free manufacturing floor when making our adhesive tape products. Every part of the space and equipment is disinfected and clean multiple times per day. All of our production lines use the latest manufacturing machinery that automates most of the manufacturing process.

Through our class 8 cleanroom space and robust manufacturing capabilities, Crown can create adhesive tape and protective film solutions that offer reliable performances for different applications.